Health and Safety within the Car Manufacturing Industry - Part 1

Many factories and workplaces have varying factors which can increase the risk of a sudden cardiac arrest and also, limit the timely delivery of potentially lifesaving treatment.

These can include:

Work sites with high voltage equipment. All high voltage equipment would need to be shut down before adequate CPR and defibrillator use could occur; your first priority as a first responder is to make the sure the area around the victim is safe and secure. This may not be as easy as simply flicking a switch. Gaining access to industrial campuses. Restricted access sites will only hamper emergency services’ attempts to gain entry to a facility; the current response time to a cardiac event is 8-14mins approx; victims lose 10% of their chances of survival with every passing minute without defibrillation. Food for thought. Multiple levels to a building. What if your cardiac victim was on the fourth floor of a warehouse and the lift was out of order? Having multiple defibrillators placed within a large working facility ensures that treatment is only a few moments away at all times.

Anything which increases time it takes for the emergency services to get to a cardiac arrest incident needs to be taken into account when debating whether or not to have an AED on site. But from our point of view, having a hospital next door would not be close enough.

If there are first responders available at the scene of a cardiac event immediately, this can drastically improve the chances of someone’s survival. Immediate cardiopulmonary resuscitation (CPR) and defibrillation can boosts a person’s chances of survival from 6% - 74%. We strongly urge that some, if not all, employees in all professions and workplaces have first aid training to benefit everyone around them.

If AEDs are inspected and maintained regularly (which includes battery and pads being checked or changed when they are about to expire) then the chances of an AED failing when they are needed the most is virtually nil. They work as intended 99.5% of the time.

They can be strategically placed within a workplace, similar to the convenience of fire extinguishers, so that responders have an immediate access to the potentially lifesaving technology.

The Manufacturing Industry

The manufacturing industry poses a multitude of occupational health and safety risks too, and if the right safety regulations are not adhered to, injuries can easily occur. Some of the key health topics within the industry as pointed out by the Health and Safety Executive are:

Metalworking fluids: Exposure to metalworking fluids which can cause irritation of the skin/dermatitis, occupational asthma, bronchitis, irritation of the upper respiratory tract, breathing difficulties or, rarely, a more serious lung disease called extrinsic allergic alveolitis (EAA). This can cause increasingly severe breathing difficulties in recurrent episodes, following repeated exposure.

Welding: Breathing welding fume can result in illness. Some welders may be ill for only a short time, others may get permanent illnesses like asthma. There is no easy way to know if it will be you. A few welders get so ill they have to stop welding and find a new career.

Noise: Noise can cause hearing damage and tinnitus (ringing in the ears). It can interfere with communication, cause fatigue and tiredness, reduce efficiency, affect morale and distract and disrupt job performance.

Cleaning and Degreasing: Various organic solvents are used in degreasing. The most commonly used are chlorinated solvents such as trichloroethylene, dichloromethane (methylene chloride) and perchloroethylene. Exposure to organic solvent vapour or liquids may be harmful to health, affecting the nervous system in particular. Ill-health effects can be both short-term and long-term and include headaches, dizziness, nausea, disorientation, unconsciousness and even death.

The Health and Safety Executive said: ‘In manufacturing over the past 5 years, each year an average of 22 workers died in workplace accidents. There was also an average of more than 3,100 reports of major injuries and about 4,100 reports of injuries that kept workers away from work for seven days or more.

Many manufacturing workers also suffer ill health from workplace exposures. It is estimated that each year an average of 33,000 workers suffer from illness caused or made worse by their current or most recent job in manufacturing (source: Labour Force Survey)

How we can help

An AED is essential for all workplaces, should an emergency situation occur, having this device accessible on site could be the very difference between the life or death of an employee or visitor.

The AED market can be confusing. You want to know that you’re spending your money on the right defibrillator. Will it work to its optimum in your environment? For instance, you will undoubtedly need a different kind of defibrillator if you work at a leisure centre than a factory shop floor. So how can you tell which is best for you?

Well all AEDs come with an IP rating which tells the customer what the AED protects against (dust , water or both) whilst you can also take a look at our buyers guide which is put together specifically to help in this situation.

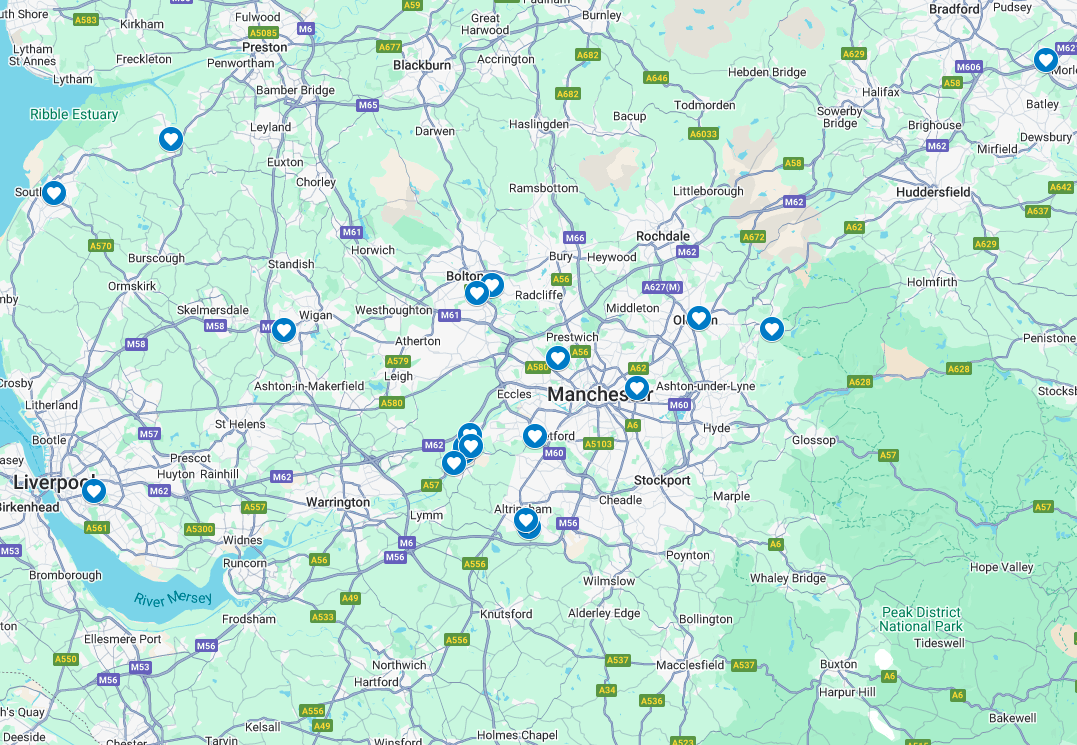

defibshop can also offer companies a site assessment form which can be used to evaluate how many defibrillators your site could need in order to optimise the safety and protection of all employees.

As well as being able to offer the best, impartial advice on all of our defibrillators, we offer first-class, nationally accredited CPR and AED training including first aid skills. All of our training courses not only adhere to, but exceed the core competencies which are laid out by the Resuscitation Council UK therefore providing you with advanced training for an emergency situation.

And once you have completed our accredited CPR and AED training courses, you’re ready to go for the next 3 years before you will be required to take a requalification course (which we also can provide) to ensure that all the skills and knowledge you have acquired in training do not fade away.

If you would like to learn more about defibrillators, the heart, cardiac arrest and everything in between then our friendly, impartial and knowledgeable defibshop team are here to help. Call us on 0845 071 0830 or alternatively head to our FAQ page which is packed full of useful information.

(photos – Oli Scarff/AFP/Getty Images)